fluid handling solutions

Solving Fluid Handling Problems Since 1985

About Phoenix Pumps

Having our customers' backs — providing you with fluid handling solutions specifically engineered for efficiency and profitability — has always been our focus. We work with the world's top fluid technology manufacturers so our customers get innovative equipment that makes a real difference in performance and help reduce total cost of ownership.Services

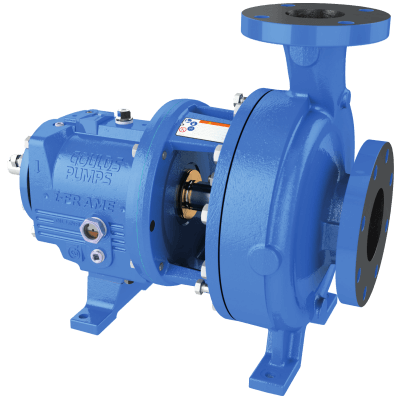

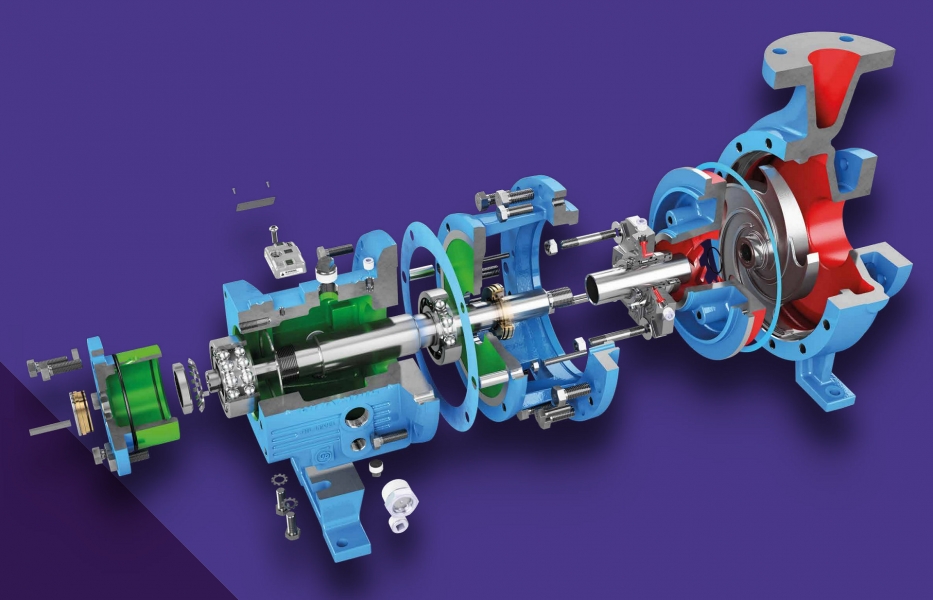

Pump Repair

Ensure fluid process equipment is fixed right the first time. Our factory-authorized certifications coupled with factory-trained service technicians, ensures you're getting the best quality pump rebuild.

See Details

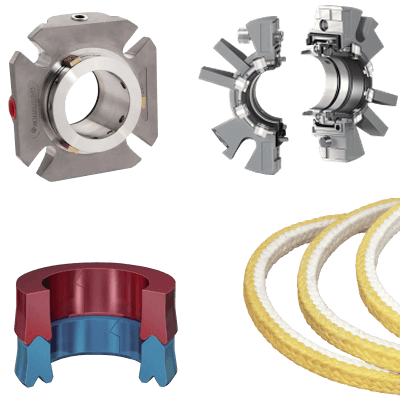

Seal Repair

Expert OEM Chesterton mechanical seal repairs conveniently located at Phoenix Pumps.

See Details

Installation & Start-Up

Proper fluid process equipment installation and start-up is vital to the long term operation. Get started on the right foot with professional installation and start-up.

See Details

Preventive Maintenance

Go From Reactive to Proactive with a Maintenance Plan from Phoenix Pumps. With a predictive or preventive maintenance plan, we'll help you minimize unscheduled repairs and plan for necessary repairs in the future.

See Details

Asset Management

Quickly access your pump asset information including specifications, manuals, videos and more.

See Details

Reliability Solutions

Customized equipment reliability solutions to maximize your plant's productivity.

See Details