5 Ways to Kill a Mechanical Seal During Installation

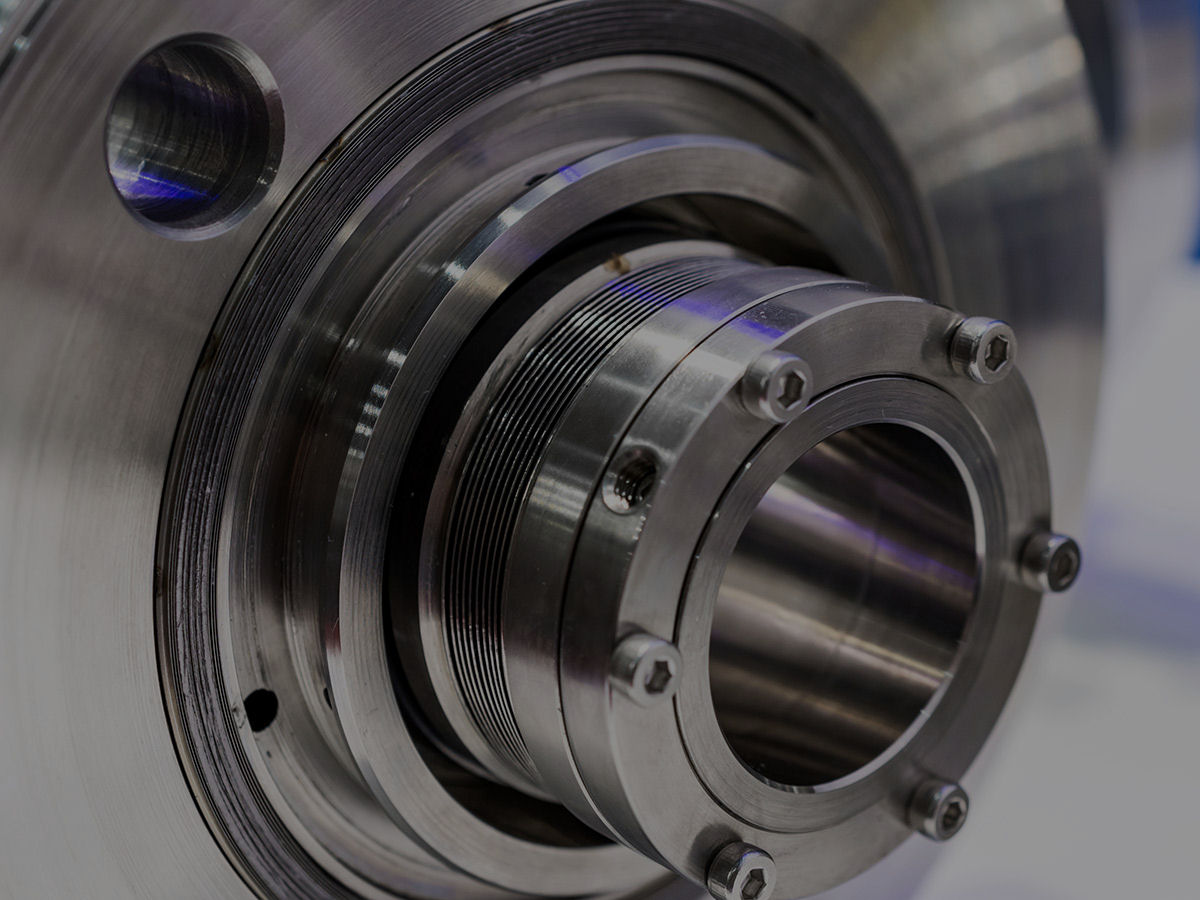

There are many things that can affect a mechanical seal's life including proper seal selection, flush plan consideration & installation. Assuming that the seal has been properly selected for the application, installation of the seal is vitally important. Below are the top 5 things to consider when installing a mechanical seal.

1. Not Following the Installation Instructions

Mechanical seals can be easily damaged during installation. That's why it is imperative to read the installation instructions carefully before installing the seal. For cartridge seals, spacers should be removed prior to operation.

2. Install on a Misaligned Pump

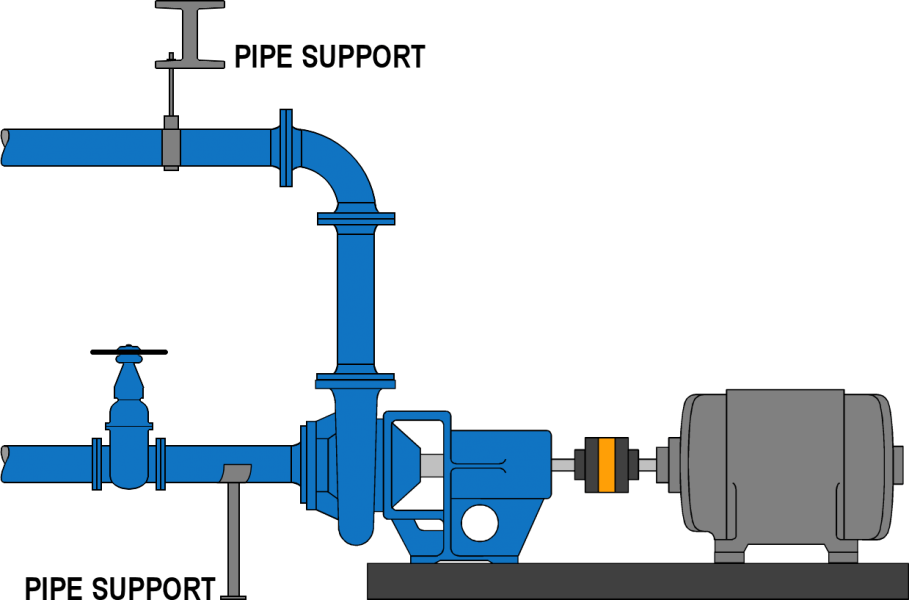

Shaft misalignment can greatly affect the life of a mechanical seal. It is important to reduce or eliminate any pipe strain to the pump by proper support. It is also recommended to align rotating shafts to shaft alignment standards and not coupling alignment standards. Shaft misalignment can cause deflection, which can lead to vibration and seal face damage.

3. Lack of or Wrong Lubrication on Shaft

Lubrication is necessary for proper mechanical seal installation. Lack thereof can damage o-rings or rubber bellows on the seal, causing them to tear, or roll. Always check the installation instructions to ensure the lubricant you choose is compatible with the seal components and the product pumped.

4. Dirty Work Surface/Hands

Dirt on the seal faces, even oil from your hands can lead to premature failure. Tiny particles can create wear and destroy seal faces, causing leakage.

Ensure proper handling during installation by following these tips:

- Don't unpack the seal until ready to install

- Wash hands

- Avoid touching or handling lapped seal faces

- Use clean tissue paper on workbench to prevent contamination

- Don't set the seal down on its face

- Clean faces with soft tissue and approved solvent before putting them together on the equipment

5. Uneven or Over-Tightening of Fasteners

This is probably one of the most common mistakes. Over-tightening fasteners can cause seal components to become distorted and leak. Oftentimes when a seal starts to leak, the natural reaction is to tighten even further! Unfortunately this just exacerbates the problem. Instead, try loosening a bit, the problem may correct itself, if the internals haven't broken already from mechanical shock.