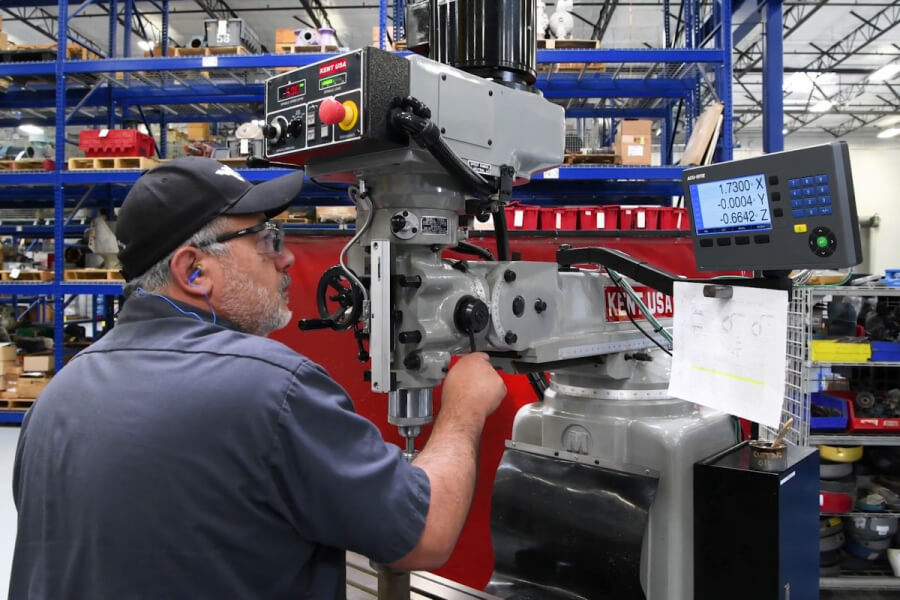

machining services

Phoenix Pumps, Inc. offers a fully equipped machine shop and our machinists have decades of experience in machining parts for rotating equipment. We specialize in providing our customers with quality machined parts, increased reliability, meeting stringent deadlines and are committed to exceptional customer service.

Quality Control

- Inspection Points Throughout the Machining Process

- Calibration Program

- Detailed Documentation

- Machine Close Tolerances That Meet or Exceed Industry Standards

Capabilities

- Dynamic Balancing - Impellers, Rotors, Fans, Drive Shafts, etc..

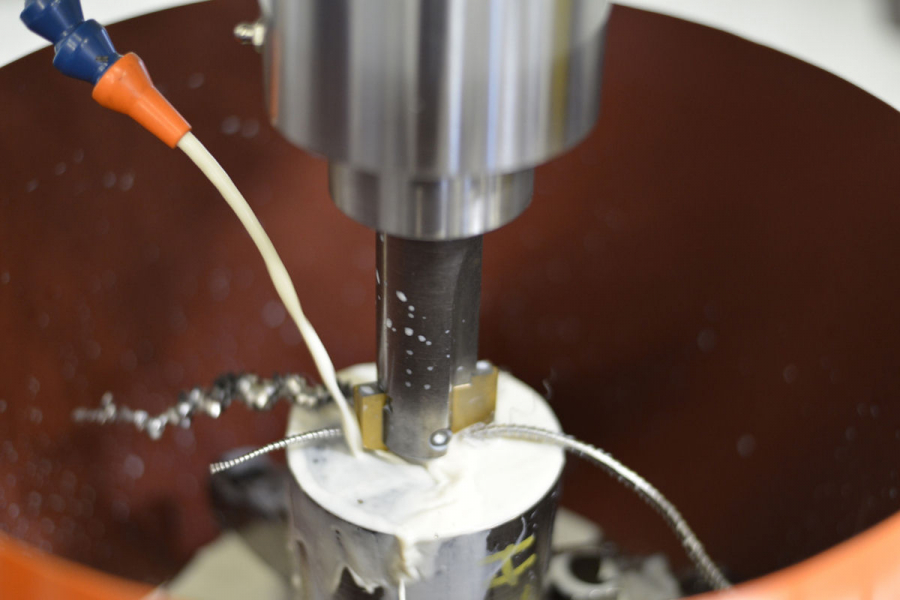

- Repair - Bearing Bores, Shafts, Rotors, Sleeves, Seal Housings, Impeller Repair, etc.

- Trimming/Balancing Impellers

- Machining New Parts - Threaded Shafts (Bowl & Line Shafts), Shafts, Couplings, Threaded Column Pipe, Impeller Wear Rings, Casing Wear Rings, Sleeves, Bushings, Sleeve Nuts, Seal Housings, Custom Parts, etc.

Materials

- Carbon Steel

- Plastic - Teflon, PVC, etc.

- Cast Iron

- Stainless Steel - 416, 304, 316, 17-4

- Hastalloy

- Nictronic 50 & 60

- CD4

- Bronze

Equipment

- Summit Precision Lathe - 28" Swing Over Bed, 12' Length

- Kent Lathe - 26" Swing Over Bed, 9' Length

- Foradia Lathe - 20" Swing Over Bed, 36" Length

- Logan Lathe - 14" Swing Over Bed, 36" Length

- Kent Mill - 12" x 50" Table

- Bridgeport Mill - 9" x 42" Table

- Excello Mill - 9" x 37" Table

- Stewart Warner Dynamic Balancer, 2000 lbs. Capacity

- Tilting Rotating Table

- Boyer-Schultze Surface Grinder