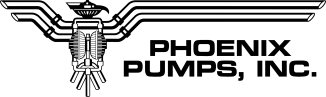

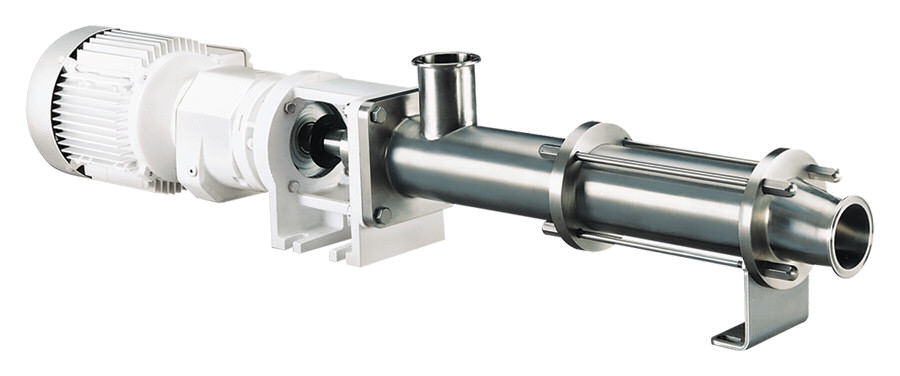

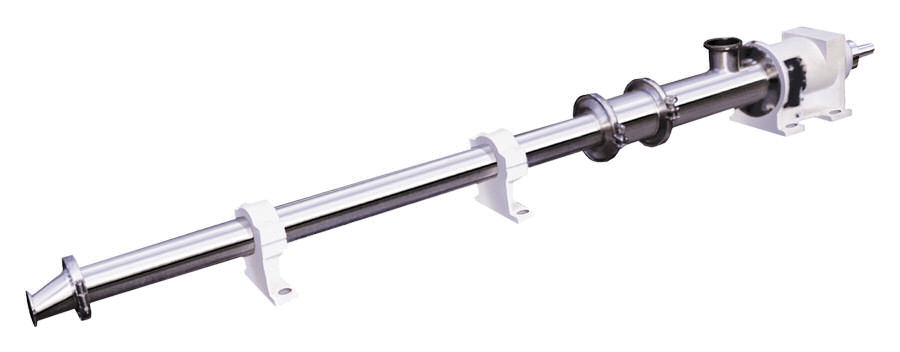

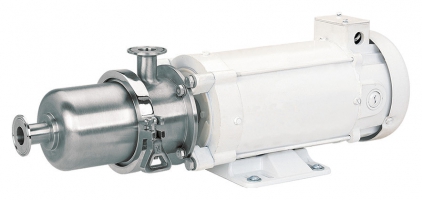

Sanitary Progressing Cavity Pumps

Sanitary Pumps

Designed to meet FDA requirements in a variety of food and chemical applications. Low-shear, non-pulsating Sanitary Pumps transfer shear-sensitive materials with a minimum of turbulence or stress.AugMentor™

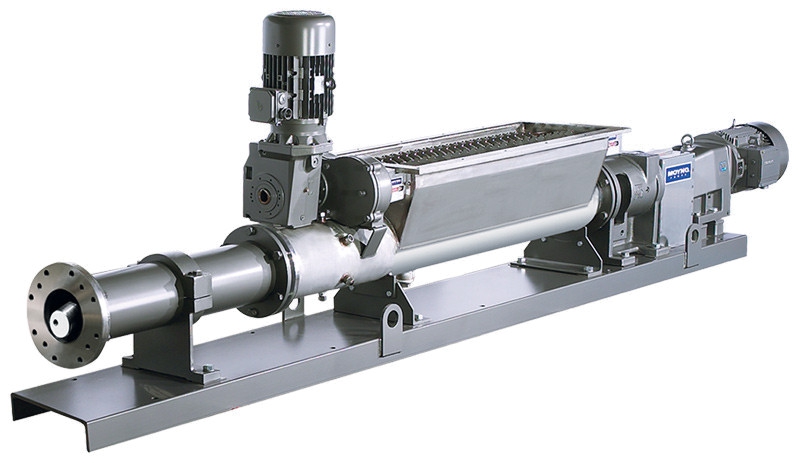

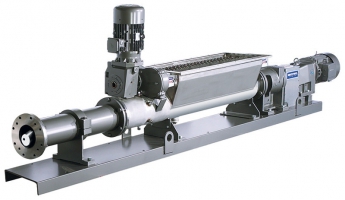

The AugMentor® Pump Stuffer handles high-viscosity materials otherwise unpumpable by conventional means. Materials in excess of 1,000,000 cps, such as cold processed meats and bakery dough, are easily fed by the AugMentor's slow-speed, bottom-drive auger.Chopper Hopper™

Moyno™ has created a food products processor that combines solids reduction and transfer pumping into one efficient unit. The patented Chopper Hopper™ is a unique and aggressive solids reduction pumping system that reduces whole produce - papayas, pineapples, pumpkins or any other fruits or vegetables - into an easy to handle puree or mash.

The Chopper Hopper™ provides fast, simple and effective handling of waste by-products. Up to three stages of solids reduction are available for coarse, medium and fine particle size.

For additional information: Manufacturer's Website

Specifications

| Flow Rates to | 345 |

| Pressures to | 500 PSI (1155' TDH) |

| Sanitary Standards | 3A, FDA |

| Temperatures to | 240º F |