Guide for a Successful Pump Installation

Installation & Start-Up Checklist

- Read and understand the instruction manual.

- Use a proper foundation. The foundation should be rigid, level and clean of debris.

- Install the base on the foundation.

- Install the pump and the driver on the baseplate.

- Add the proper oil to the proper level in the bearing housings (pump, gear reducers, etc.)

- Check initial alignment.

- Ground the base to the foundation.

- Install piping. Read piping guidelines below.

- Complete a second alignment check, and readjust piping as needed.

- With the coupling element removed, complete a rotational check of the driver.

- Verify correct pump settings.

- Install ancillary equipment.

- Install coupling and/or insert.

- Complete the pre-startup check procedure; fill and vent the pump and system, and check the system valve and component "lineup".

- Recheck alignment to ensure that fluid weight in the piping didn't cause a change in the alignment.

- Start the unit.

- Check for proper indicators such as pressures, flows, temperature, vibration and noise.

- Recheck alignment. Perform "hot alignment" if fluid is above 200°F.

Every pump original equipment manufacturer (OEM) has its own requirements for its specific pump models and applications.

Foundation

The success to pump longevity begins with a strong foundation. In general, a pump should be mounted on a strong baseplate and supported by a strong concrete foundation. The pump should be properly aligned to the motor as well as to the piping system.

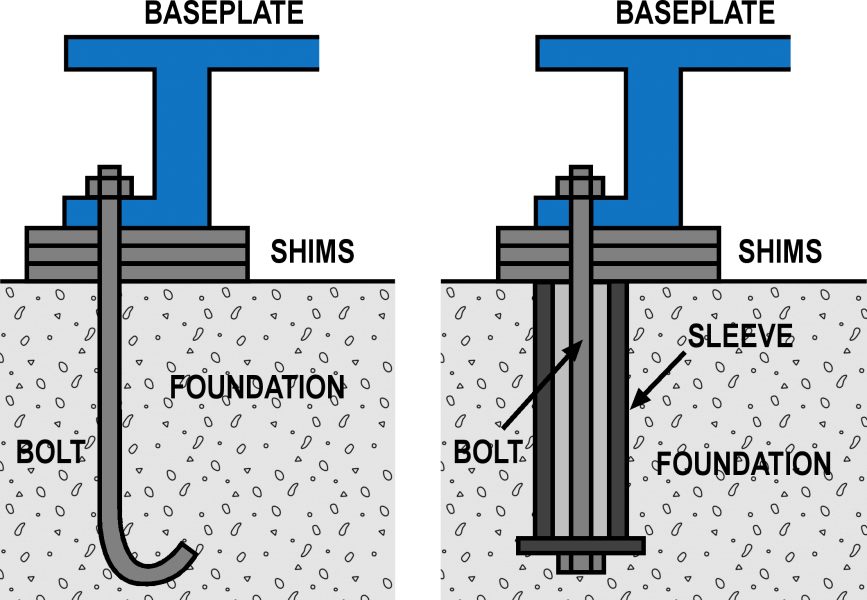

The concrete foundation must be substantial enough to absorb any vibration and form a permanent rigid support for the baseplate. The anchor bolts are usually of sleeve type—or the "J" type—shown above and must be located in accordance with the certified outline drawing of the baseplate.

The entire surface of the foundation should be leveled by chipping away any defective concrete, leaving it rough, but level. The surface must then be freed of all oil, grease and loose particles. While individual practices vary throughout industry, there is a tendency in most leading companies to remove the pump and driver from the baseplate prior to installation. This facilitates leveling of the base and in removing any distortion.

The baseplate should be supported on leveling screws, shims or metal wedges with a small taper located close to the foundation bolts. All leveling screws and other areas that require protection from grout spatter should then be covered with a wax to prevent the grout from adhering to them. Check the machined mounting surfaces on the baseplate by adjusting the leveling devices and using a precision level. Ensure that the baseplate's machined mounting surfaces are horizontal, flat and parallel. To prevent stress and distortion of the equipment, all surfaces in the same plane must be within 0.002" overall.

When the baseplate is level, check that all support wedges or shims are in full contact with the foundation and baseplate. Tighten the foundation anchor bolts evenly and double check the level.

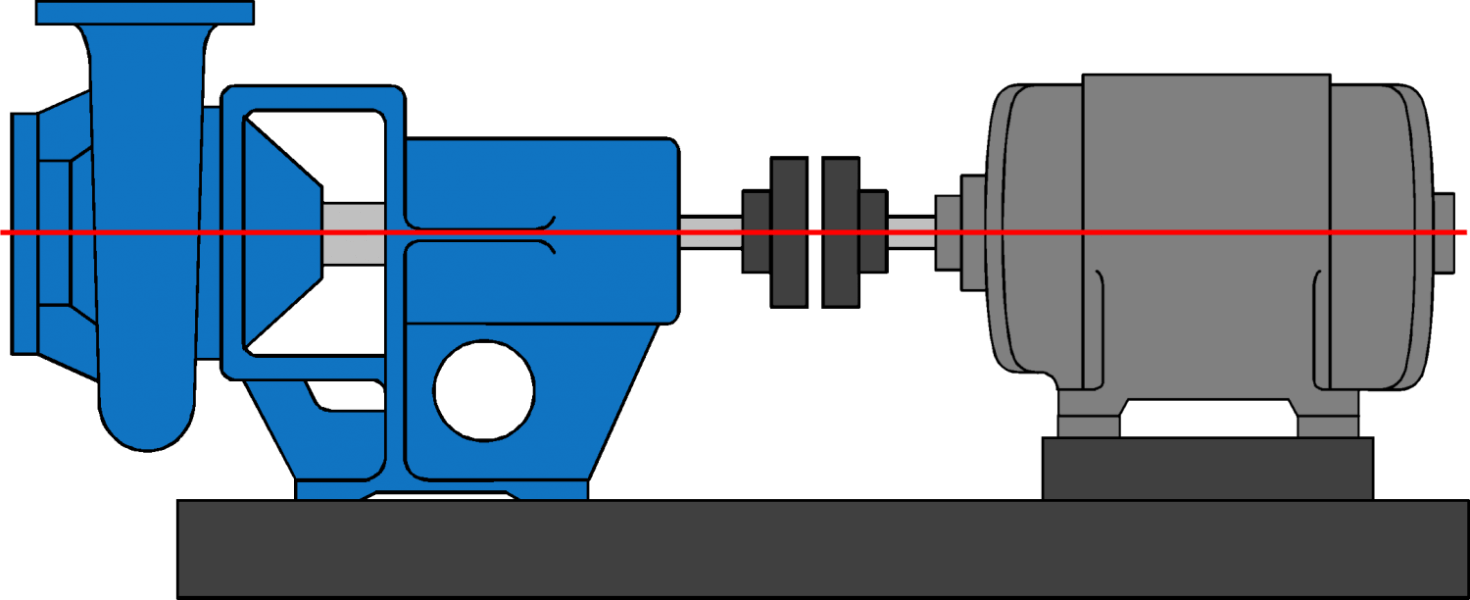

Shaft Alignment

Proper shaft alignment is critical to the equipment's life. This means that the pump and motor shaft are collinear across both horizontal and vertical planes. In order to maintain proper shaft alignment, you should begin with proper pipe alignment and support.

Please note that many pump skids come aligned from the manufacturer. However, alignment should be rechecked after installation and prior to startup. See above checklist for more information.

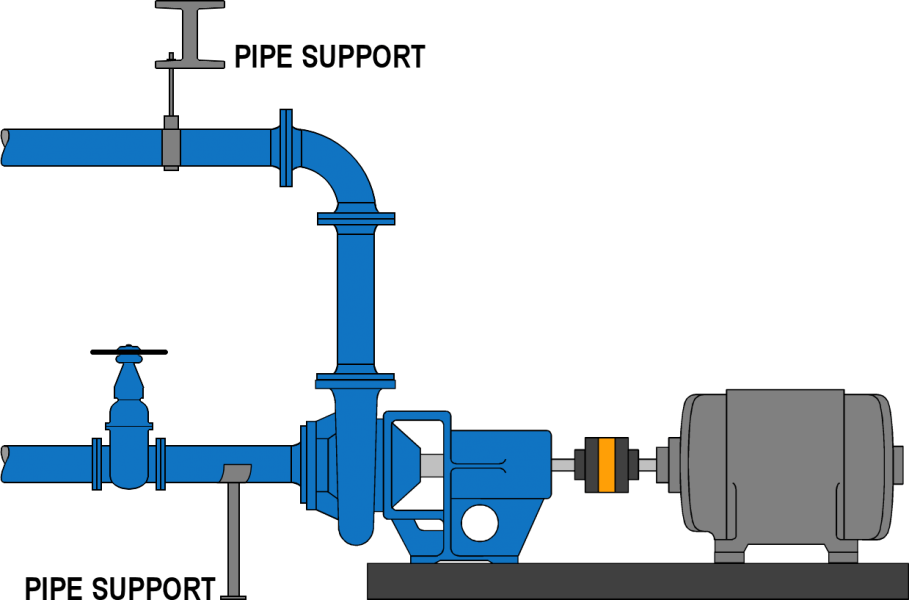

Proper Pipe Support

Both the suction and discharge piping should be aligned and independently supported so that the pipe doesn't create any undesired strain against the fluid connections of the pump. Pipe strain is a leading factor in causing shaft misalignment. Pipe support should be balanced so that when fluid is introduced, there is no movement that would cause pipe strain on the pump.

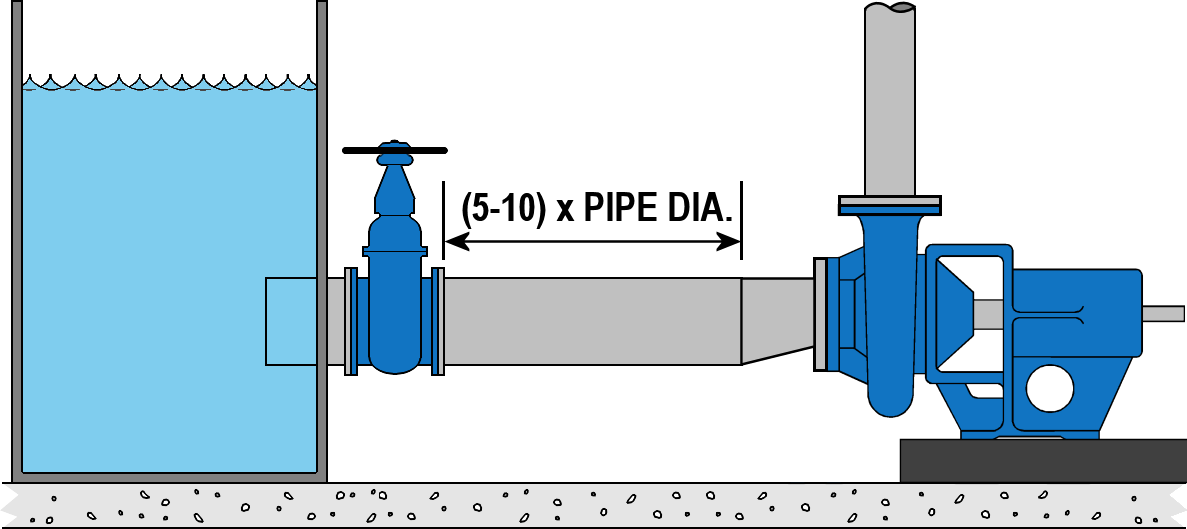

Suction Piping

As a rule of thumb the suction side with a straight pipe run, in a length equivalent to 5 to 10 times the diameter of that pipe, between the suction reducer and the first obstruction in the line. This will reduce turbulence into the pump, which reduces unwanted vibration.

Shaft Alignment Checks

A second alignment should be performed after piping installation and prior to start-up. While some shaft couplings can compensate for some slight shaft misalignment, it is still recommended to align equipment to the manufacturer's specifications and not the coupling's specifications.

Shaft misalignment can lead to premature seal and bearing failure and often caused by the following:

- Improper mounting/shimming of the equipment.

- Pipe strain caused by improper alignment to the pump's fluid connections

- Pipe strain cause by improper support of the pipe.

Rotation Direction

Prior to starting the equipment, it is extremely important that you uncouple the pump before you check rotation of the driver. Running a pump in reverse rotation for even short time periods can cause catastrophic failure. Some pumps utilize threaded impellers, which can unscrew if run in the opposite designed direction. Even pumps with keyed impellers and lock nut can also hydraulically loosen in time.

Pre-Startup Check & Startup Procedure

Fill and vent the pump and system. Check the system valve "lineup". Review and verify the preceding steps were accomplished. Remember, you cannot vent a running pump; the fluid will come out, but the air trapped in the center of the machine will remain. The fluid has more mass and will be flung to the outside.